What is pressure mapping?

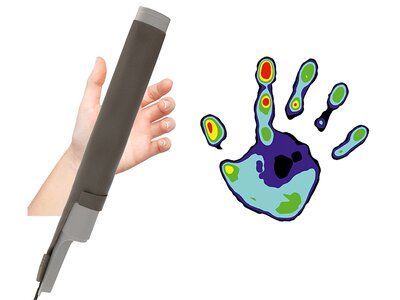

Pressure mapping or pressure distribution measurement is the art of measuring individual pressures between two (soft) objects with high local resolution, accurately and precisely without affecting the objects themselves.

When developing products or studying people or objects, simplified models are often used to categorize or classify forces or loads. In doing so, important information is lost and the results do not contain the answers to the actual questions. To fully understand the interactions between soft objects, pressure mapping can be an essential tool. Only with the measurement of pressure distribution the deformation of soft objects can be analysed and the occurrence of pressures determined.

How pressure distribution measurement can be used?

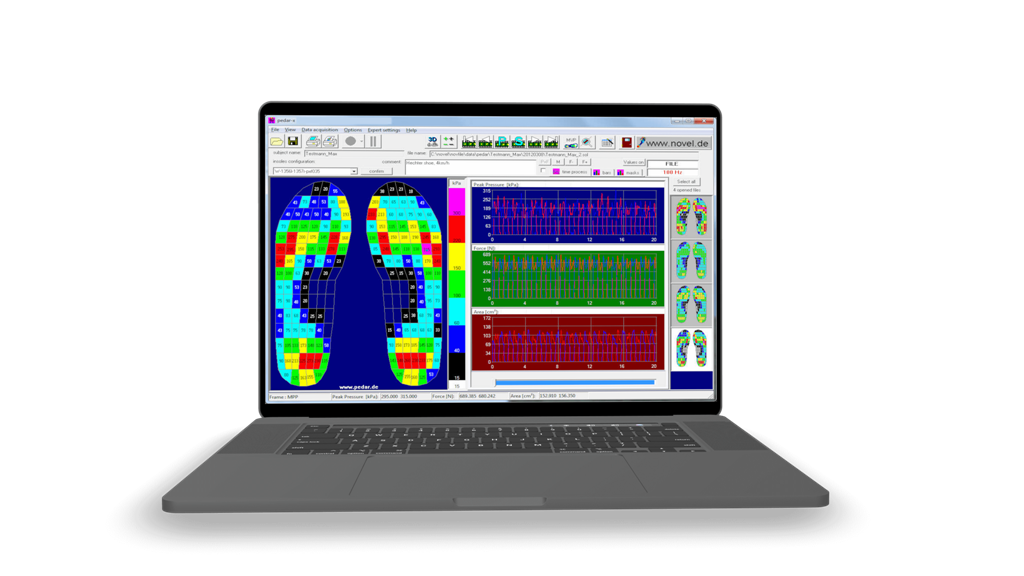

Today, pressure distribution measurement and pressure mapping are used in a wide range of industries. Measurements are used in real time for control or for sustainable, long-term analysis of processes. With the information of the pressure distribution, phenomena such as pressure peaks, deformations, pressure ulcers in medicine, gait analysis, body pressure mapping and etc. can be recorded and investigated.

It is important that the measuring system and sensor used are suitable for the application, so that the sensor provides reliable values and does not influence the measurement itself. The highest reliability is provided by so-called capacitive sensors. They allow to analyze highly dynamic as well as inert or static loads.

What else to consider when mapping pressure?

An important aspect is the calibration and adjustment of the sensors. Since the sensors of pressure distributions have to be divided into individual zones, calibration and adjustment must be possible for each zone. A measuring system is suitable if: • the drift of the measuring signal is low (e.g. with capacitive or resistive sensors) • has a hysteresis that is as low as possible/suitable for the measurement (e.g. capacitive or piezoresistive sensors) • has a constant displacement force curve (e.g. capacitive sensors). Therefore, resistive sensors are NOT suitable for measurements with more than 5 measuring cycles. Note that Piezo sensors are NOT suitable for measurements where the force is applied both dynamically and statically.